NiAl cladding powder me ka ikaika hoʻopaʻa ikaika

wehewehe

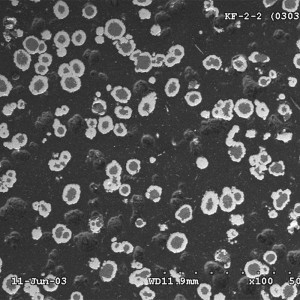

Haʻaheo mākou e hoʻolauna i ʻelua huahana e pili ana i ka pauka NiAl: KF-2 a me KF-6.Hoʻohana kēia mau huahana ʻelua i nā ratio like ʻole o ka pauka NiAl a loaʻa iā ia nā hiʻohiʻona kūikawā a me nā noi.

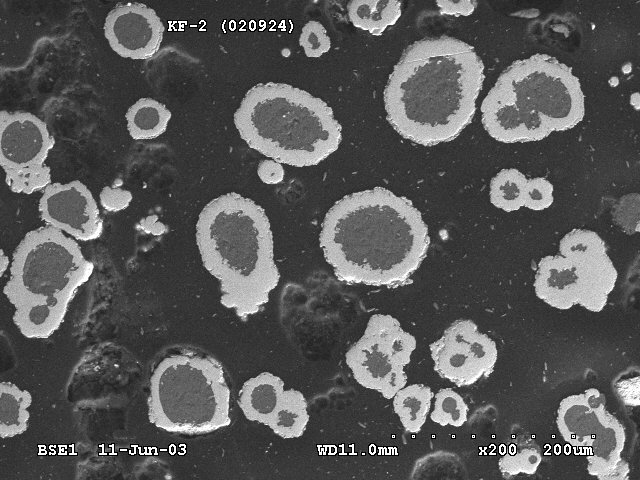

Hoʻohana ʻo KF-2 i ka NiAl82/18, nona ka 82% Ni a me 18% Al.He kūpono kēia huahana no nā noi me ka mahana hana kiʻekiʻe loa o 650°C.Hāʻawi ia i kahi uhi paʻa, machinable, oxidation-resistant, a me nā mea hoʻopaʻa paʻa ponoʻī.Loaʻa mau ka hopena exothermic i ka wā o ke kaʻina hana hoʻoheheʻe, e hopena i ka ikaika paʻa maikaʻi loa ma mua o ka mea Ni5Al.Kūpono ʻo KF-2 no ka hoʻoponopono ʻana a me ka hana hou ʻana i ke kila kalapona machinable a me ke kila corrosion-resistant, a hiki ke hoʻohana ʻia no ka hoʻopaʻa ʻana i nā papa o nā seramika a me nā mea hiki ke komo.

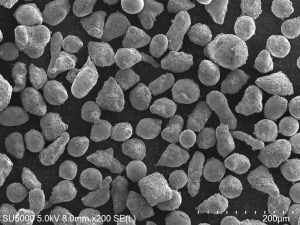

Hoʻohana ʻo KF-6 i ka NiAl95/5, nona ka 95% Ni a me 5% Al.He kūpono kēia huahana no nā noi me kahi mahana hana kiʻekiʻe loa o 800 ° C a hiki ke hoʻohana ʻia me ka hoʻohana ʻana i nā ʻano hoʻoheheʻe like ʻole e like me ka lapalapa, APS, a me HVOF.Hāʻawi pū ia i kahi uhi paʻa, machinable, oxidation-resistant, a me nā mea hoʻopaʻa paʻa ponoʻī.Loaʻa mau ka hopena exothermic i ka wā o ke kaʻina ʻana, e hopena i ka ikaika hoʻopaʻa maikaʻi.Hiki ke hoʻohana ʻia ʻo KF-6 no ka hoʻoponopono ʻana a me ka hana hou ʻana i ke kila kalapona machinable a me ke kila pale corrosion, a me ka hoʻopaʻa ʻana i nā papa o nā seramika a me nā mea hiki ke komo.

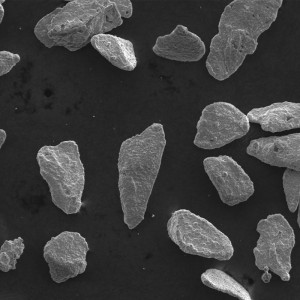

I ka hōʻuluʻulu ʻana, ʻo KF-2 a me KF-6 nā huahana NiAl i hoʻokumu ʻia i ka pauka e hāʻawi i ka ikaika hoʻopaʻa maikaʻi a me ke kūpaʻa ʻana.ʻO KF-2, kahi haʻahaʻa haʻahaʻa o ka pauka NiAl (NiAl82 / 18), kūpono no nā noi me ka mahana hana kiʻekiʻe o 650 ° C, ʻoiai ʻo KF-6, me ka hapa kiʻekiʻe o ka pauka NiAl (NiAl95/5), hiki ke mālama i nā mahana kiʻekiʻe a hiki i 800°C a hiki ke hoʻohana ʻia me ka hoʻohana ʻana i nā ʻano hana hoʻoheheʻe.He kūpono nā huahana ʻelua no ka hoʻoponopono ʻana a me ka hana hou ʻana i ke kila kalapona machinable a me ke kila corrosion-resistant, a no ka hoʻopaʻa ʻana i nā papa o nā seramika a me nā mea hiki ke hoʻohana ʻia.ʻO ke koho ma waena o KF-2 a me KF-6 e pili ana i nā koi kikoʻī o ka noi a me ka mahana hana kiʻekiʻe e pono ai.

Nā huahana like

| Brand | inoa mea kūʻai | AMPERIT | METCO/AMDRY | WOKA | PRAXAIR | PAC |

| KF-2 | NiAl82/18 | 404NS | ||||

| KF-6 | NiAl95/5 | 282 | 956450NS | NI-109 | 906 |

Hōʻike

| Brand | inoa mea kūʻai | Kemika (wt%) | ʻoʻoleʻa | Mahana | Nā waiwai a me ka noi | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Al | W | Mo | Cr | Al2O3 | MoS2 | WC | C | Fe | Ni | |||||

| KF-2 | NiAl82/18 | 20 | ʻO Bal. | HRC 20 | ≤ 800ºC | •Ke ahi, APS, Max.ka mahana hana 650°C. •ʻOi a machinable oxidation kū'ē aʻaʻahu kū'ē. | ||||||||

| KF-6 | NiAl95/5 | 5 | ʻO Bal. | HRC 20 | ≤ 800ºC | • Ke ahi, APS, HVOF, Max.ka mahana hana 800°C •ʻOi a machinable oxidation kū'ē aʻaʻahu kū'ē | ||||||||

| KF-20 | Ni-MoS₂ | 22 | ʻO Bal. | HRC 20 | ≤ 500ºC | • Hoʻohana ʻia no nā ʻāpana hoʻopaʻa hoʻoneʻe a me nā apo hoʻopaʻa wili hiki ke wili ʻia • Hiki ke hoʻohana 'ia e like me ka haʻahaʻa friction mea | ||||||||

| KF-21T | Ni-Graphite 75/25 | 25 | ʻO Bal. | HRC 20 | ≤ 480ºC | •Ke ahi, Max.ʻO ka mahana hana 480 ° C 1. Ke hoʻohana nei i nā mea o ka turbo compressor • Pili i ka nickel alloy a me nā ʻāpana kila • Ua kūpono nā huahana me ka graphite kiʻekiʻe no nā ʻāpana titanium me ka ʻole o ka lihi • E hoʻonui ka maʻiʻo graphite kiʻekiʻe i ka hana lubrication • E hoʻomaikaʻi ka ʻike nickel kiʻekiʻe i ka pale ʻana i ka erosion • ʻOkoʻa nā huahana like ʻole ma muli o nā kikoʻī OEM like ʻole | ||||||||

| KF-22T/R | Ni-Graphite 60/40 | 50 | ʻO Bal. | HRC 20 | ≤ 480ºC | |||||||||

| KF-21R | Ni-Graphite 75/25 | 25 | ʻO Bal. | HRC 20 | ≤ 480ºC | |||||||||

| KF-45 | Ni-Al2O3 77/23 | 23 | ʻO Bal. | HRC 40 | ≤ 800ºC | • Ke ahi, APS, maʻamau • Hiki ke hoʻohana ʻia i ka hoʻoheheʻe ʻana i ka crucible, ka ili hoʻopaʻa hope a me ka ʻili o ka lepo e like me ka papa pale | ||||||||

| KF-56 | Ni-WC 16/84 | ʻO Bal. | 12 | HRC 62 | ≤ 400ºC | • Ke ahi, APS, maʻamau • 'O ke kū'ē i ka hāmare, ka erosion, abrasion a me ka sliding abrasion | ||||||||

| KF-50 | Ni-WC10/90 | ʻO Bal. | 10 | HRC 62 | ≤ 400ºC | •Ke ahi, ʻaʻole maʻamau • 'O ke kū'ē i ka hāmare, ka erosion, abrasion a me ka sliding abrasion | ||||||||

| KF-91Fe | Fe-WC | 4 | 27 | 9.5 | ʻO Bal. | 5.5 | HRC 40 | ≤ 550ºC | • Ke ahi, APS, maʻamau, Max.ka mahana hana 815°C. •E hoʻohana i nā mea hoʻouhi pale, hiki ke hoʻohana ʻia no ka hoʻoponopono ʻana i ka pahu pahu pahu | |||||

| KF-110 | NiCr-Al 95/5 | 5 | 7.5 | ʻO Bal. | HRC 20 | ≤ 800ºC | •Ke ahi, APS, Max.ka mahana hana 980°C. • ʻO ka pulupulu ʻana me ka hoʻopaʻa ʻana iā ia iho | |||||||

| KF-113A | NiCrAl-CoY2O3 | Cr+Al:20, Ni+Co:75 | HRC 20 | ≤ 900ºC | •APS,HVOF, maʻamau, Max.ka mahana hana 980°C. Ua pili ia i ka hoʻoponopono ʻana i nā ʻāpana hoʻopaʻa wela kiʻekiʻe a i ʻole nā ʻāpana i hana pono ʻole ʻia | |||||||||

| KF-133 | NiMoAl | 5 | 5 | ʻO Bal. | HRC 20 | ≤ 650ºC | • Hoʻopaʻa paʻa iā ia iho, ka uhi paʻakikī maʻamau no ka noi ʻana • Paʻakikī, me ka maikaʻi o ka corrosion kū'ē a me ka hopena i ka hana • Hoʻohana ʻia no nā ʻāpana mīkini, ka noho ʻana a me ka valve | |||||||

| KF-31 | Ni-Diatomite 75/25 | • Ke ahi, APS, maʻamau, Max.ka mahana hana 650°C. • No ka uhi sila hiki ke wili, me na apana sila movable, na apo sila hiki ke wili, na mea ha'aha'a ha'aha'a. | ||||||||||||