Ni-Graphite Cladding pauka me ka uila conductivity

wehewehe

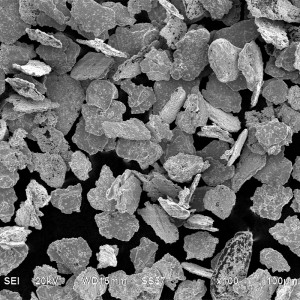

ʻO ka pauka Ni-Graphite Cladding kahi mea kūikawā kūikawā i hana ʻia e hāʻawi i ka hana ʻoi aku ka maikaʻi ma ke koi ʻana i nā noi ʻoihana.Hoʻopili ʻia kēia pauka hou me kahi kiʻekiʻe o ka nickel a me ka graphite, e lilo ia i mea koho kūpono no ka hoʻohana ʻana i nā mea o nā turbo compressors, nickel alloy, a me nā ʻāpana kila.

ʻO kekahi o nā hiʻohiʻona koʻikoʻi o ka pauka Ni-Graphite Cladding ʻo kona ʻike kiʻekiʻe graphite.Hoʻonui kēia ʻano i ka hana lubrication o ka pauka, e lilo ia i koho kaulana no ka hoʻohana ʻana i nā ʻāpana titanium i nele i kahi kihi.Hoʻohui ʻia, hoʻomaikaʻi ka ʻike nickel kiʻekiʻe o ka pauka i kona kūpaʻa erosion, e hōʻoiaʻiʻo ana e hāʻawi i ka hana maikaʻi loa i nā wahi ʻoihana paʻakikī.

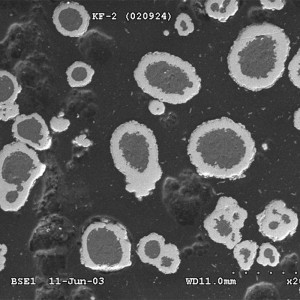

Loaʻa ka pauka Ni-Graphite Cladding i ʻelua mau ʻano hoʻohālikelike: KF-21 Ni-Graphite 75/25 a me KF-22 Ni-Graphite 60/40.Loaʻa i kēia mau papa hana ʻelua nā ʻano like ʻole o ka nickel a me ka graphite maʻiʻo, e kūpono iā lākou no nā ʻano hana ʻoihana like ʻole.No ka laʻana, ʻo KF-21 Ni-Graphite 75/25 ka mea ʻoi aku ka nui o ka nickel content, no laila kūpono ia no ka hoʻohana ʻana i nā noi e koi ana i ka pale ʻana i ka erosion.

Ma waho aʻe o kāna mau hiʻohiʻona kiʻekiʻe, ʻo Ni-Graphite Cladding powder ka mea maʻalahi loa.Hiki ke hoʻohana ʻia i loko o kahi ākea o nā noi ʻoihana, me nā compressors turbo, nickel alloy, a me nā ʻāpana kila.Eia kekahi, ʻo kona kūpaʻa ahi a me ka mahana hana kiʻekiʻe o 480 ° C e lilo ia i koho hilinaʻi no ka hoʻohana ʻana i nā noi wela kiʻekiʻe.

I ka wā e koho ai i ka pauka Ni-Graphite Cladding pono no kāu noi ʻoihana, he mea nui e noʻonoʻo i nā kikoʻī OEM kikoʻī o kāu mau lako.Ua like ka KF-21 me AMPERIT 205, METCO/AMDRY 307NS, PRAXAIR NI-114, a me PAC 138, aʻo KF-22 e like me AMPERIT 200 a me Durabrade 2211.

I ka hopena, ʻo Ni-Graphite Cladding powder kahi mea kūikawā nui e hāʻawi i ka hana kiʻekiʻe ma ke koi ʻana i nā noi ʻoihana.ʻO kāna ʻike graphite kiʻekiʻe a me ka ʻike nickel kiʻekiʻe he koho maikaʻi loa ia no ka hoʻohana ʻana i nā mea hana o nā turbo compressors, nickel alloy, a me nā ʻāpana kila.Me kona versatility, flame resistance, a me ka wela hana kiʻekiʻe, ʻo Ni-Graphite Cladding powder kahi koho hilinaʻi no ka nui o nā noi ʻoihana.

Nā huahana like

| Brand | inoa mea kūʻai | AMPERIT | METCO/AMDRY | WOKA | PRAXAIR | PAC |

| KF-21T/R | Ni-Graphite 75/25 | 205 | 307NS | NI-114 | 138 | |

| KF-22T/R | Ni-Graphite 60/40 | 200 | ʻO Durabrade 2211 |

Hōʻike

| Brand | inoa mea kūʻai | Kemika (wt%) | ʻoʻoleʻa | Mahana | Nā waiwai a me ka noi | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Al | W | Mo | Cr | Al2O3 | MoS2 | WC | C | Fe | Ni | |||||

| KF-2 | NiAl82/18 | 20 | ʻO Bal. | HRC 20 | ≤ 800ºC | •Ke ahi, APS, Max.ka mahana hana 650°C. •ʻOi a machinable oxidation kū'ē aʻaʻahu kū'ē. | ||||||||

| KF-6 | NiAl95/5 | 5 | ʻO Bal. | HRC 20 | ≤ 800ºC | • Ke ahi, APS, HVOF, Max.ka mahana hana 800°C •ʻOi a machinable oxidation kū'ē aʻaʻahu kū'ē | ||||||||

| KF-20 | Ni-MoS₂ | 22 | ʻO Bal. | HRC 20 | ≤ 500ºC | • Hoʻohana ʻia no nā ʻāpana hoʻopaʻa hoʻoneʻe a me nā apo hoʻopaʻa wili hiki ke wili ʻia • Hiki ke hoʻohana 'ia e like me ka haʻahaʻa friction mea | ||||||||

| KF-21T | Ni-Graphite 75/25 | 25 | ʻO Bal. | HRC 20 | ≤ 480ºC | •Ke ahi, Max.ʻO ka mahana hana 480 ° C 1. Ke hoʻohana nei i nā mea o ka turbo compressor • Pili i ka nickel alloy a me nā ʻāpana kila • Ua kūpono nā huahana me ka graphite kiʻekiʻe no nā ʻāpana titanium me ka ʻole o ka lihi • E hoʻonui ka maʻiʻo graphite kiʻekiʻe i ka hana lubrication • E hoʻomaikaʻi ka ʻike nickel kiʻekiʻe i ka pale ʻana i ka erosion • ʻOkoʻa nā huahana like ʻole ma muli o nā kikoʻī OEM like ʻole | ||||||||

| KF-22T/R | Ni-Graphite 60/40 | 50 | ʻO Bal. | HRC 20 | ≤ 480ºC | |||||||||

| KF-21R | Ni-Graphite 75/25 | 25 | ʻO Bal. | HRC 20 | ≤ 480ºC | |||||||||

| KF-45 | Ni-Al2O3 77/23 | 23 | ʻO Bal. | HRC 40 | ≤ 800ºC | • Ke ahi, APS, maʻamau • Hiki ke hoʻohana ʻia i ka hoʻoheheʻe ʻana i ka crucible, ka ili hoʻopaʻa hope a me ka ʻili o ka lepo e like me ka papa pale | ||||||||

| KF-56 | Ni-WC 16/84 | ʻO Bal. | 12 | HRC 62 | ≤ 400ºC | • Ke ahi, APS, maʻamau • 'O ke kū'ē i ka hāmare, ka erosion, abrasion a me ka sliding abrasion | ||||||||

| KF-50 | Ni-WC10/90 | ʻO Bal. | 10 | HRC 62 | ≤ 400ºC | •Ke ahi, ʻaʻole maʻamau • 'O ke kū'ē i ka hāmare, ka erosion, abrasion a me ka sliding abrasion | ||||||||

| KF-91Fe | Fe-WC | 4 | 27 | 9.5 | ʻO Bal. | 5.5 | HRC 40 | ≤ 550ºC | • Ke ahi, APS, maʻamau, Max.ka mahana hana 815°C. •E hoʻohana i nā mea hoʻouhi pale, hiki ke hoʻohana ʻia no ka hoʻoponopono ʻana i ka pahu pahu pahu | |||||

| KF-110 | NiCr-Al 95/5 | 5 | 7.5 | ʻO Bal. | HRC 20 | ≤ 800ºC | •Ke ahi, APS, Max.ka mahana hana 980°C. • ʻO ka pulupulu ʻana me ka hoʻopaʻa ʻana iā ia iho | |||||||

| KF-113A | NiCrAl-CoY2O3 | Cr+Al:20, Ni+Co:75 | HRC 20 | ≤ 900ºC | •APS,HVOF, maʻamau, Max.ka mahana hana 980°C. Ua pili ia i ka hoʻoponopono ʻana i nā ʻāpana hoʻopaʻa wela kiʻekiʻe a i ʻole nā ʻāpana i hana pono ʻole ʻia | |||||||||

| KF-133 | NiMoAl | 5 | 5 | ʻO Bal. | HRC 20 | ≤ 650ºC | • Hoʻopaʻa paʻa iā ia iho, ka uhi paʻakikī maʻamau no ka noi ʻana • Paʻakikī, me ka maikaʻi o ka corrosion kū'ē a me ka hopena i ka hana • Hoʻohana ʻia no nā ʻāpana mīkini, ka noho ʻana a me ka valve | |||||||

| KF-31 | Ni-Diatomite 75/25 | • Ke ahi, APS, maʻamau, Max.ka mahana hana 650°C. • No ka uhi sila hiki ke wili, me na apana sila movable, na apo sila hiki ke wili, na mea ha'aha'a ha'aha'a. | ||||||||||||